Achieving egg weight loss during incubation

Tags: Incubation | Whitepaper

, 5 January 2026

For optimal hatch results and chick quality, eggs need to lose sufficient weight during incubation. The aim should be 11–12% egg weight loss at transfer (18 days) compared to the original fresh egg weight. This weight loss is due to water evaporating from the eggs through the pores in the eggshell, causing the air cell size to gradually increase. The air cell should be sufficiently large to allow the fully developed ready-to-hatch embryo to internally pip (pierce its beak into the air cell). This allows the embryo to inflate its lungs to initiate lung respiration and gradually become independent of gas exchange through the chorioallantoic membrane (CAM).

If egg weight loss is too low, the air cell will be too small and internal pipping and lung inflation will be more difficult. In practise, it is very rare for egg weight loss to be too high, although it could occur in shells of very poor quality.

How to check egg weight loss?

The egg weight loss can be easily checked by weighing a sufficiently large sample (6–10 setter trays) at start of incubation and the same trays at transfer before candling. Setter trays do not lose weight, so exclude the weight of the empty tray from the calculation. Also, correct for eggs that are missing (exploders) or visibly damaged, in which case the calculation should be based on the average weight of the remaining good eggs.

What if egg weight loss is too low?

The main driving force behind water evaporation from the eggs is the water vapour pressure inside the setter, which largely depends on the relative humidity (RH%). Eggs will lose less weight at a higher RH% and more at a lower RH%. Temperature also plays a – much smaller – role: water will evaporate more easily out of an egg at a higher temperature with equal RH%. The altitude of the hatchery also matters; water diffuses more easily through the pores at high altitude.

Therefore, if egg weight loss is too low, the RH% should be reduced, either for the entire setter period or specific periods. Setter ventilation also plays a role, but more indirectly as the rate of air refreshment affects the RH% inside the setter. Keeping the damper closed at the start of incubation results in a high RH%. In that case, reducing the RH% set point will not influence the real RH% inside the setter, which will remain high. Instead, a logical action could be to start ventilating earlier. A higher ventilation rate towards the end of incubation is associated with a lower RH%, unless the air supply has a high water content. Furthermore, reducing the RH% set point in the final days in the setter will have no effect if the ventilation rate is already at 100% and the real RH% above its set point. Lowering the water content of the supply air could be an option. Often, the best time to reduce the RH% set point is the middle of the setter period. As a positive side effect, this might also reduce the activation of the humidifiers.

Advice

- Check egg weight loss if there are concerns about hatch results or chick quality.

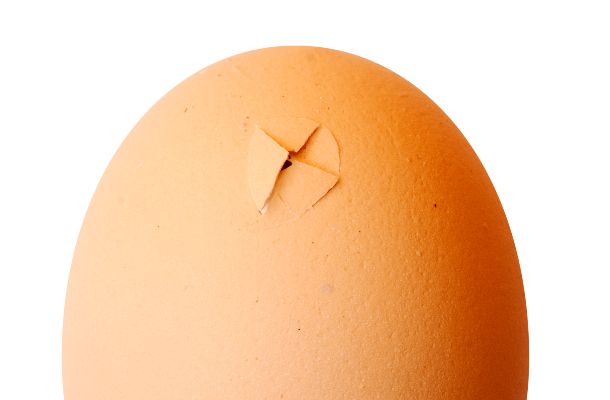

- Monitor the pipping height of empty shells or pipped unhatched eggs: ‘high pips’ (see photo) is a sign of low egg weight loss.

- Different breeds, flock ages and breeder flocks may have different shell conductance causing egg weight loss issues, and therefore might require a different incubation profile.

- Adjust RH% set points and ventilation rate if needed to correct egg weight loss issues.

- Correct egg weight loss in case of early or late transfer by recalculation to 18 days.

- Consider that some weight loss will occur in the egg store in the case of long storage (approx. 0.5%/week).

Written by Gerd de Lange

Senior Poultry Specialist

I welcome your feedback on this article - and if you require any additional information, please don't hesitate to contact me.